Is chaos having an effect on your circuit building?

It is said that there is nothing new in the universe and nothing is

further from the truth. Every nanosecond is unique and nothing is ever

repeated. No matter how many times you do anything, that seems repetitive,

it is not. Every physical element has changed from one moment to the next

and for the most part, these minute changes have little effect on the

outcome of most procedures. So many of the changes are so infinitesimal that

they are not even perceived.

Every now and then, circumstances beyond your perceptions seem to

conspire to frustrate your efforts to do meaningful work. Our universe was

born out of chaos called the big bang, and chaos is everywhere.

Each and every grain of sand is uniquely shaped, as is each and every

speck of dust or particle in the air. There are no exact duplicates of

anything and each and every particle has characteristics unique to it. This

makes substances, to one degree or another, inconsistent.

Subatomic Consistency

Subatomic particles cannot be seen and will always remain just theory. If

the character of mater in basic physics is patterned in a given fashion,

then it is reasonable to assume that the same or similar exists on the

quantum level, or does it? That is a question, which will not be answered

anytime soon.

Chaotics

"Chaotics is the study of the predictability of complex systems." as Jeff

Goldblum explains to Laura Dern in the movie "Jurassic Park". Because of the

inconsistency of matter, there is more often no predictability. The number

of significant variables in substances and conditions make manufacturing of

anything accurate only within a plus to minus factor.

Randomness is the rule of the universe and this complicates any

organizational process. Anything that contributes to the deterioration,

decomposition, or alteration of any substance may be considered an element

of chaos. Corrosion, oxidation, decay, atmospheric temperature differential

and tensile stress, as well as elements we are not aware of can produced

changes in solid material.

Order

Order is an illusion. It is an invention of man for the

purpose of control and to create aesthetically pleasing visual environments.

Symmetry is that which seems equal in all planes and it is also an illusion.

It is difficult to understand how the quantum community could even entertain

the idea of a singularity because of the inconceivable set of circumstances

necessary to create such an unlikely phenomenon. Equal pressure from all

angles is just not a symmetric possibility.

What's it all about

What does all this have to do with electronics? Since electronic

components are made of substances that are imperfect, then imperfect devices

will be the results. For example, substances used in the manufacture of

resistors is rated at plus to minus a percentage. Transistors with the same

component number behave differently in the same circuit. In addition, heat

generated by components can change the value of that and other components.

Dust and other floating debris as well as chemical content of the atmosphere

can complicate the circuit design process. Even unknown factors can have an

effect on the circuit designing process as evidenced by the fact that

sometimes even veteran circuit designers have given up on prototypes with

extremely stubborn problems.

What to do

Because of the infinite number of variables, chaos is all around us and

it has an effect on everything, and that includes your project. Research

laboratories work on component fabrication in clean rooms that are, for all

practical purposes, free of dust. Chairs and floors are made of conductive

material that prevents static charges from building up. Despite this, even

manufacturers make a dud on occasion. It is not necessary for you to go to

these extremes, however, you can take a few steps to assure your success. It

is a good idea that you also choose a clean, cool, well lit workbench.

Organization is helpful in keeping on top of potential problems.

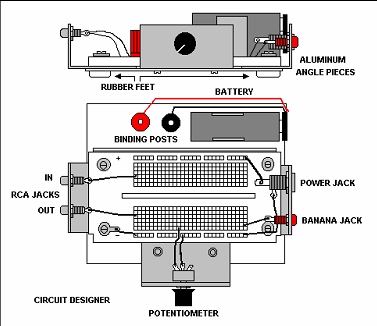

Circuit designer

It is always best to breadboard a project before you try building it.

This allows you to experiment with a variety of components to optimize the

design. Circuit designers, like the one illustrated in this article, can go

a long way to organize your projects. The board itself can be purchased at

your local supplier and when mounted as shown, can make your work more

stable and productive.

The size used in the unit, pictured in this article, measures 2 1/8 by 3

5/8 and contains 23 rows of 5 clips for circuit connection and 2 rows of 20

clips to supply power to the circuit.

As we see in the diagram, a 4-inch by 4-inch piece of Masonic, combined

with 4 rubber feet, serves as a base for the board. A piece of aluminum foil

placed under the board makes an electrical connection between three angle

pieces that act as a hum shield.

Two RCA phono jacks are mounted on one of the angle brackets to connect

to other circuits. A power jack, connected to another angle bracket, enable

the use of an external AC wall unit and a banana jack is also provided. A 9-volt

battery clip is also provided for a freer operation. Don’t forget to disconnect

the battery when using the wall power supply unit.

The circuit board contains rows of clips that provide a solid connection

to any component lead that is inserted into the proper contact hole.

Sometimes the leads do not go into the holes easily so needle nose pliers

can come in handy. The holes spaced to match the pin placement of integrated

circuits. They snap in easily and make stable contact that will assure an

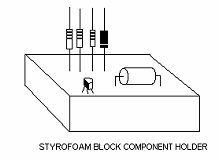

operating circuit. A piece of Styrofoam can be used to store the components

until they are used on the circuit designer.

Connection to other circuits is easily accomplished with the two RCA

phono jacks and adjustment of circuit parameters can be made with the

built-in potentiometer. Shielding provided by the angle brackets should keep

the circuit free of radio and other distortion producing AC signals. Wires

that are used to connect the circuit should also be given a continuity test.

Component preparation

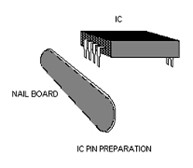

Component leads are without a doubt the most bothersome problem when

trying to get a circuit working. Integrated circuits are the worst offenders

because of the number of pins. Most ICs have a number of pins that have

enough corrosion to interfere with proper operation and the best way to

handle this is a manicurists nail board rubbed lightly over both sides of

the flat pins until you see them shine.

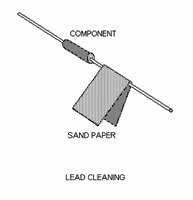

Resistors also tend to have corroded leads and a quick swipe with sandpaper

or scouring pad will assure clean contact. The same goes for capacitors and other components.

Testing

All components should be tested before using in the circuit designer.

Some components, such as LEDs, can be tested on the designer with a small

circuit off to the side. Transistors should be tested with a reliable

transistor tester. Resistors and diodes can be tested with a multimeter.

Resistors

Resistors are made with plus to minus value rating. If there is no fourth

color band on the resistor, there is as much as 20% value variance. If the

4th band is silver, the possible variance is 10% and if the 4th band is

gold, the rating is within 5%. Critical circuits may function better with

more accurate resistors. Precision resistors are also available that are the

most accurate and can run low as 1% but they can be quite expensive.

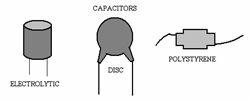

Capacitors

Capacitors that pass the signal from one stage to the next tend to

be less critical when it comes to design parameters, while capacitors

that connect the signal to ground, impart a timing or filter element that

can be quite critical. There are different types of capacitors, disc,

polystyrene, electrolytic, etc. You might try a different type of capacitor

for a given job for it might make a difference.

Integrated circuits can be tested in IC testers, but if you don’t have

one, the circuit you are designing will serve as a tester. If the IC runs

hot, make sure the proper pin connections are made and every thing is properly

in place and if the IC continues to run hot, then the IC is probably bad so try another IC.

If all components have been tested the circuit is wired correctly and it

doesn’t work, then remove everything from the designer board, take a break,

have a drink, and start over in a different place on the designer board. Even

replacing a component with another of the same value may do the trick.

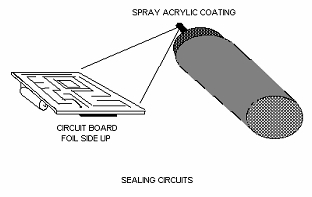

Foil pattern

If you choose to use foil circuit boards there are a few things you should

keep in mind. After you have chosen the board, you should clean it with one of the

commercial steel wool scouring pads and water, until it is shiny. This will assure

that the etching solution will remove all of the excess copper. Make sure that

the etchant bath has removed all of the unwanted copper from the board before removing it.

When you do remove the circuit board, rinse it off with cold water and then

use the scouring pad again to expose the remaining copper. If there are any short

circuits due to excess copper, use a mat knife to scrape of the excess. After the

circuit board is completed, you may want to spray the board with an acrylic sealant.

This will prevent any short circuit if the board should come in contact with a wire

or any other conductive element. The spray can be purchased at any art supply store.

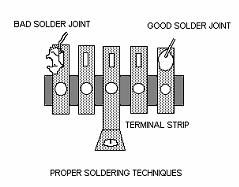

Solder

Another problem that can cause circuits to malfunction is poor soldering techniques.

Solder joints should look shiny and smooth, not jagged and dull as shown in the illustration.

You should work on some small projects to develop your skills.

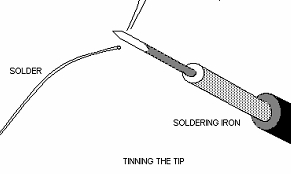

Only use rosin core solder (acid core solder is not for electronic circuits), and

make sure that the soldering iron is hot enough to melt the solder. One way to assure

this is to tin the tip. This is accomplished by melting the solder and let it cover the

very tip of the soldering iron.

Tinning the tip of the iron will make soldering easier. The best technique to soldering

is to heat the work, the foil pattern, or the lug, or tie point, and then touch the solder

to the heated area and let the solder flow over the work. Solder quickly for heat from solder

can burn out components like transistors and ICs, in fact it is best to use sockets when

working with integrated circuits.

If all fails

Circuits for the most part go together quite easily, but every now and then, one gives

you trouble and you just cant figure what is the matter. What you must do is get away from

it for a while, clear your head and then start from scratch. After doing this once, I came

back to the circuit and saw the most obvious mistake you could imagine and every thing

went perfectly after that. "How could I have missed that?" I kept saying too myself.

Conclusion

Chaotic elements may complicate your task in ways you will never be aware of so

you must do what you can to increase your chances for success. This is most important

for the beginner, for failure has greater impact on their confidence. For veteran

experimenters, it can reduce some of the frustration on complex circuit designs. Make

sure that you use these proper procedures, so that the next time a butterfly flaps its

wings, somewhere in the world, your circuit doesn't explode in front of you.

by Terence Thomas (t1t7t91@yahoo.com)